Laser Micromachining of Ceramic Materials

Ceramic materials are used for multiple applications in industries. Unique properties of ceramics, such as dielectric strength, thermal and chemical stability, mechanical properties and hardness, make them the material of choice for design engineers.

The need for smaller high-precision parts drives the technology development to apply laser micromachining to ceramic materials. Small features can be micromachined onto ceramics without heat affected zones or microcracking while producing good edge quality.

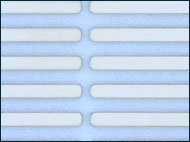

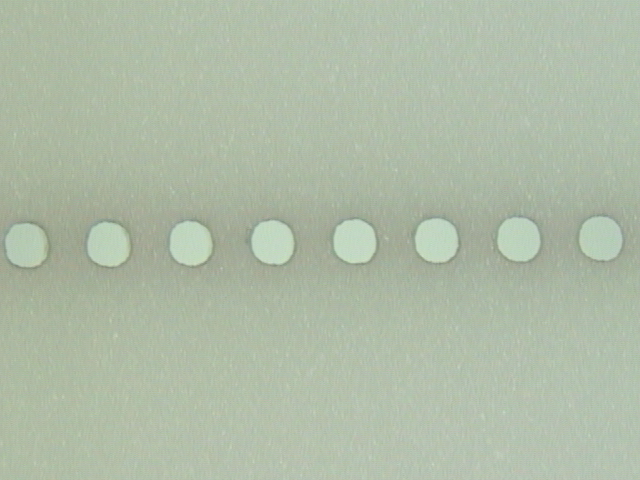

Basic applications for laser micromachining applied to ceramic materials include producing small holes and/or slots of any shape through wafers, cutting out (singulation) of devices from wafers, machining conductive coatings on the surface (selective machining) without any damage to the ceramic body.

Alumina Slots0.005 inch geometry

Alumina Holes0.005 inch diameter holes onto Alumina Ceramic